Intelligent Subcontractor Scoring System and Risk Management in Renewable Energy Infrastructure Contracts

AI and automation

More about case study Intelligent Subcontractor Scoring System and Risk Management in Renewable Energy Infrastructure Contracts

The construction of wind and solar farms is a process involving a vast network of subcontractors, from construction firms to specialized electrical teams. In this operating model, the quality and timeliness of external work determine the developer's final margin. Choosing the wrong partner - one who fails to meet safety standards or delays key assembly stages - can generate losses amounting to millions due to contractual penalties and lost energy production revenue.

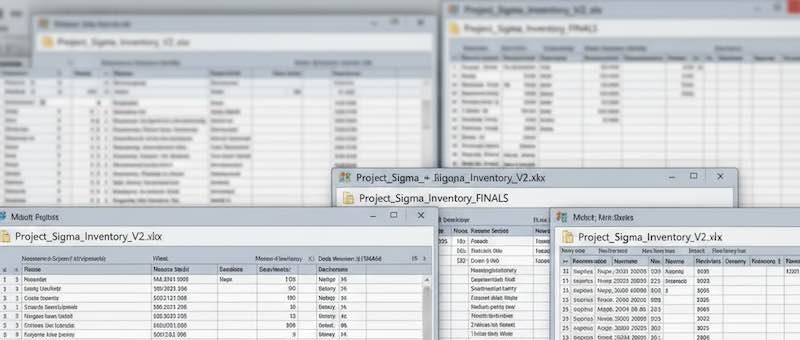

Traditional supplier assessment methods, based on subjective employee opinions or scattered Excel notes, do not provide sufficient protection for the company’s interests. The lack of a unified system for collecting historical cooperation data results in repeated mistakes, as information about defects does not flow between implementation teams.

Implementing digital oversight of the supplier base enables not only a reduction of operational risks but also procurement cost optimization by rewarding the most efficient entities. Centralizing knowledge about subcontractor performance shifts business relationships from trust-based to data-driven, which is critical for safely scaling operations in the renewable energy sector.

About the client

The client is a significant player in the renewable energy market, executing long-term infrastructure contracts across Central Europe. The scale of operations requires cooperation with over a hundred subcontractors annually, which - combined with a dispersed project structure - made reliable performance assessment challenging.

Knowledge about problematic suppliers remained with site managers, while procurement teams, lacking access to these insights, repeatedly contracted the same firms for new projects, exposing the organization to recurring operational risks.

The challenge

The primary issue was the absence of "institutional memory" regarding errors and failures caused by external firms. Although information about defects and delays existed within service ticketing systems, it was never correlated with future contractor selection processes.

As a result, procurement decisions were often driven by the lowest bid, without awareness that certain subcontractors generated warranty repair costs exceeding initial savings. Additionally, the lack of a centralized registry for certificates and permits created legal and compliance risks due to manual, ad-hoc verification processes.

Our approach

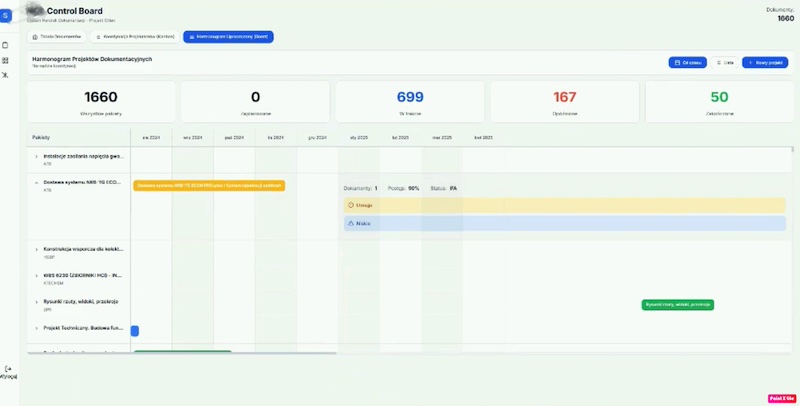

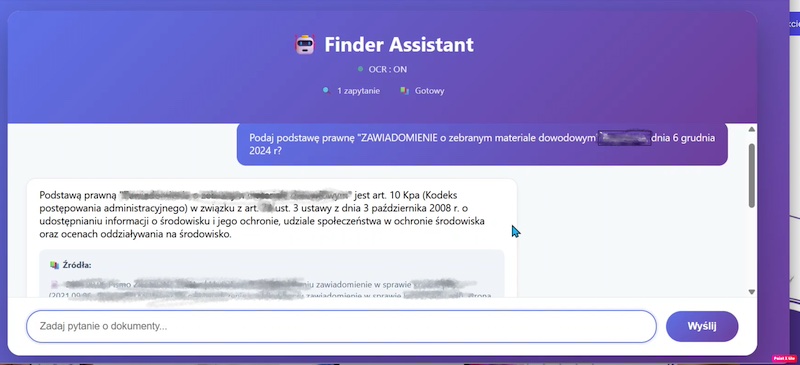

We implemented a Proof of Concept for an intelligent subcontractor registry, integrating it with existing document management and ticketing systems. A key element was the development of a scoring algorithm that automatically retrieves defect data from the service system and assigns it to individual subcontractors.

We defined four core metrics: timeliness, work quality (number of defects), HSE compliance, and responsiveness during the warranty period. The system architecture was built on SharePoint as the document repository and Power BI as the analytical layer.

The PoC pilot covered 30 of the most active subcontractors, reconstructing their cooperation history over the past 24 months. This enabled validation of the scoring model and demonstrated a clear correlation between low scores and actual financial losses.

Key platform capabilities

Central subcontractor register - a single source of truth containing partner data, contract history, and competency scope.

Automatic scoring system - real-time performance evaluation based on implementation and service data.

Compliance and certificate repository - automated monitoring of permits, liability insurance, and industry certifications.

Warranty cost analysis - linking service repair costs to specific subcontractors to calculate real project margins.

Blacklist and risk alerts - early-warning mechanism preventing the selection of critically low-rated suppliers.

Strategic significance

Transitioning to an objective subcontractor assessment model eliminated information silos between implementation and procurement teams. The resulting data foundation enables further automation of contractor selection and forms the basis for predictive analytics, allowing project risks to be identified before execution begins.

Challenge

- Lack of institutional memory on subcontractor failures

- Procurement decisions driven by lowest price, not performance

- Manual and fragmented compliance verification

Solution

- Centralized subcontractor registry with historical performance data

- Automated, data-driven scoring model integrated with service systems

- Digital compliance repository with risk alerts

Results

The pilot revealed that 15% of subcontractors were responsible for nearly 60% of total warranty repair costs. Armed with this insight, procurement teams were able to immediately adjust contracting strategies and avoid the highest-risk partners.

A 40% reduction in the participation of "blacklisted" firms in new tenders resulted in direct savings within service and maintenance budgets.

Automated compliance checks reduced supplier verification time by 70%. The estimated ROI for full-scale implementation of the supplier management system reached 180% within 24 months, primarily through reduced delay penalties and fewer warranty claims.

From a management perspective, the solution significantly increased operational safety and enabled more deliberate, data-driven supply chain governance across the organization.